A rubber compound is raw rubber precisely mixed with selected additives to achieve targeted performance goals. Like following a recipe, chemists adjust ingredients and proportions to fine-tune properties such as flexibility, durability, chemical resistance, and cost-effectiveness.

Through compounding, raw rubber is transformed into an engineered material optimized for its environment. Whether resisting automotive engine heat, industrial chemical exposure, or outdoor UV degradation, each compound of rubber is designed for its application and balanced for reliable performance and production efficiency.

Why Custom Compounding Matters

Different applications demand different properties. Automotive seals face heat and oil exposure, while roofing membranes must withstand UV rays and fluctuating temperatures. Custom rubber compounding ensures materials perform in their intended environments while avoiding unnecessary costs. By selecting the right polymer and additives, manufacturers achieve durable, reliable parts without over-engineering every formulation.

Key Rubber Compound Additives

A successful rubber compound depends on carefully selected additives, each playing a distinct role:

- Curing Agents – Sulfur or peroxide systems create cross-links during vulcanization, giving rubber its strength and elasticity.

- Fillers – Carbon black and other reinforcements enhance strength, stiffness, or resistance to aging.

- Processing Aids – Improve flow during mixing and molding while preventing sticking.

- Antiozonants & Stabilizers – Guard against cracking, fading, and other damage from environmental exposure.

- Plasticizers – Modify flexibility, improve processability, and adjust temperature performance.

ALTTRAN’s Approach to Custom Compounding

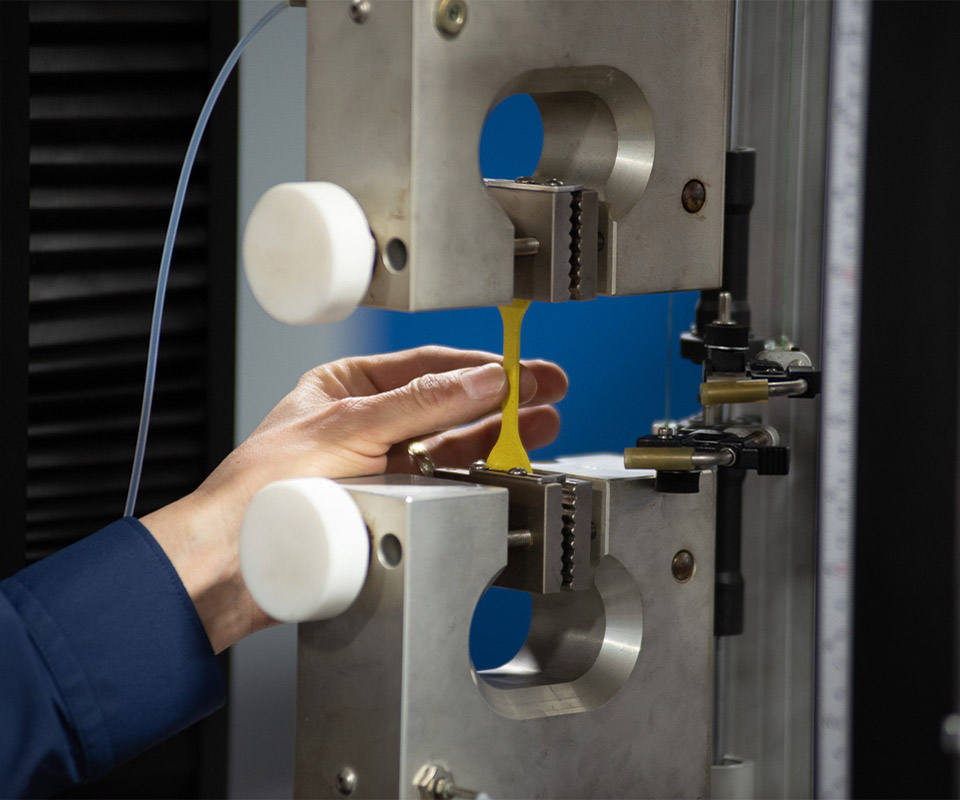

At ALTTRAN, every formulation begins with understanding the customer’s end use. Our rubber testing lab studies confirm physical properties and mixing methods before scaling to production, ensuring consistency and eliminating surprises on the factory floor.

Our services cover the full development process, from rubber formulation and lab-scale trials to production planning and ASTM D-2000 call-out confirmation. We also perform product performance evaluations and raw material validation. By combining technical expertise with hands-on collaboration, ALTTRAN delivers practical solutions to even the most complex rubber and elastomer challenges.

Natural vs. Synthetic Rubber Compounds

- Natural Rubber (NR): Offers excellent tensile strength and elasticity, ideal for tires and vibration mounts, but less resistant to oils and high heat.

- Synthetic Rubbers: Provide targeted advantages:

- NBR (Nitrile): Oil resistance for automotive seals and fuel hoses.

- EPDM: Outstanding weather and UV resistance for roofing and outdoor uses.

- SBR: Cost-effective durability for general industrial applications.

- HNBR or CR (Neoprene): Excellent resistance to heat, oil, and chemicals.