Types of

Rubber Testing

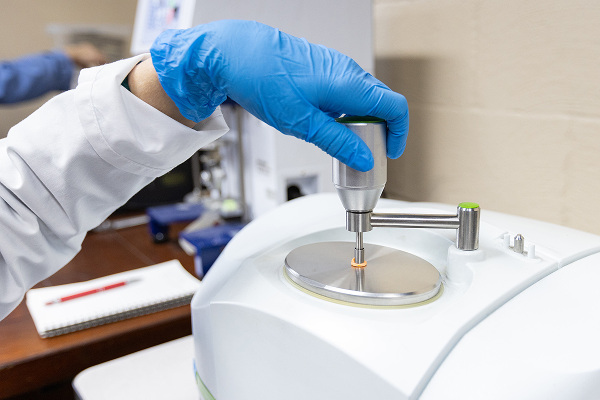

Our expert rubber testing is backed by industry experience.

We provide real-world solutions for rubber and elastomer formulation challenges, no matter how complex your application.

Our ALTTRAN Technical Services team utilizes ASTM-standard rubber testing methods and ALTTRAN Test Methods (ATM) for rubber compound testing to ensure your materials meet or exceed performance expectations.

From temperature fluctuations to tensile and tear strength, our lab technicians test your rubber formulations to refine performance before production. Need a custom formulation? We can develop the ideal rubber compound for your specific requirements.

With decades of industry experience, our rubber testing methods are backed by expert professionals dedicated to delivering high-quality, consistent, and performance-driven rubber products.

Let’s talk rubber testing

Share your info, and let’s connect!

* Required

* Required

Our rubber testing in ASTM methods include:

ALTTRAN RUBBER MIXING

Polymer types we mix:

| Butyl & Halobutyl | (IIR, CIIR, BIIR) |

| Carboxylated Nitrile | (XNBR) |

| Hydrogenated Nitrile | (HNBR) |

| Nitrile Butadiene Rubber | (NBR) |

| Chlorosulfonated Polyethylene | (CSM) |

| Ethylene Propylene Diene Monomer | (EPDM) |

| Natural Rubber | (NR) |

| Polybutadiene | (BR) |

| Polychloroprene | (CR) |

| Polyisoprene | (IR) |

| Styrene Butadiene Rubber | (SBR) |

| Nitrile/PVC | (NBR/PVC) |

ALTTRAN Technical Services (ATS)

Improving materials and processes:

Rubber formulation development

Lab to scale up production planning

Confirm ASTM D-2000 call-outs

Product performance evaluation

Raw material validation and recertification

Data development for technical marketing programs

Lab mixing

Custom rubber compound formulation

Compound Mixing

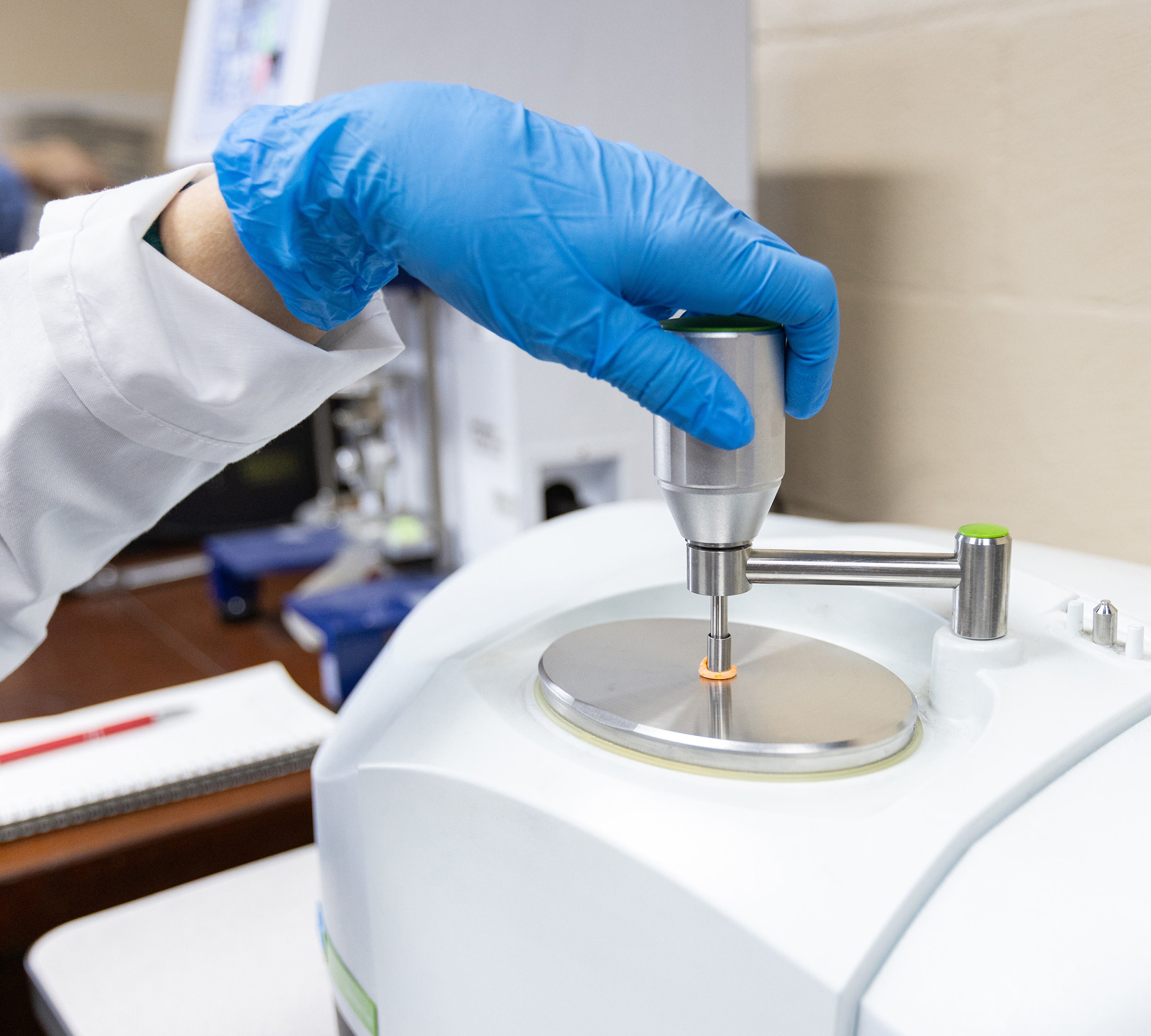

Molding Process Simulation with RPA

Rubber problem solving

ATS TEST LAB

Analytical Testing

| FTIR | ASTM E 573 |

| FTIR – Microscope | ASTM E334 |

| TGA for Compound Analysis | ASTM E1131 |

| TGA for Rubber Composition | ASTM D6370 |

Unaged Physical Testing

| Moving Die Rheometer | D5289 |

| Rubber Process Analyzer | D6204/D6601 |

| Viscosity & Scorch | D1646 |

| Durometer | D2240 |

| Tensile Strength | D412 |

| Green Strength | D6746 |

| Tear Strength | D624 |

| Tension Set | D412 |

ALTTRAN RUBBER MIXING

Polymer types we mix:

| Butyl & Halobutyl | (IIR, CIIR, BIIR) |

| Carboxylated Nitrile | (XNBR) |

| Hydrogenated Nitrile | (HNBR) |

| Nitrile Butadiene Rubber | (NBR) |

| Chlorosulfonated Polyethylene | (CSM) |

| Ethylene Propylene Diene Monomer | (EPDM) |

| Natural Rubber | (NR) |

| Polybutadiene | (BR) |

| Polychloroprene | (CR) |

| Polyisoprene | (IR) |

| Styrene Butadiene Rubber | (SBR) |

ALTTRAN Technical Services (ATS)

Improving materials and processes:

Rubber formulation development

Lab to scale up production planning

Confirm ASTM D-2000 call-outs

Product performance evaluation

Raw material validation and recertification

Data development for technical marketing programs

Lab mixing

Custom rubber compound formulation

Compound Mixing

Molding Process Simulation with RPA

Rubber problem solving

ATS TEST LAB

Analytical Testing

| Butyl & Halobutyl | (IIR, CIIR, BIIR) |

| Carboxylated Nitrile | (XNBR) |

| Hydrogenated Nitrile | (HNBR) |

| Nitrile Butadiene Rubber | (NBR) |

| Chlorosulfonated Polyethylene | (CSM) |

| Ethylene Propylene Diene Monomer | (EPDM) |

| Natural Rubber | (NR) |

| Polybutadiene | (BR) |

| Polychloroprene | (CR) |

| Polyisoprene | (IR) |

| Styrene Butadiene Rubber | (SBR) |

The Role of Rubber Testing in Material Optimization

Rubber compound testing allows us to fine-tune formulations, ensuring that materials meet the exact demands of their intended applications. Whether it's increasing tensile strength for high-stress environments or improving chemical resistance for industrial seals, our rubber testing methods provide critical insights.

By utilizing a combination of types of rubber testing, such as compression set analysis, tear resistance evaluation, and accelerated aging studies, we help manufacturers optimize their rubber formulations for superior long-term performance. This level of precision ensures that every compound we test is engineered for reliability, efficiency, and compliance with customer and application specification.

Polymer Material Performance Testing

While rubber is our primary focus, many of the ASTM and ISO test methods we use also apply to other polymers and specialty materials. Properties such as tensile strength, hardness, tear resistance, weathering, and electrical performance are universal measures in polymer material performance testing. By applying these standards beyond rubber, manufacturers can validate the performance of plastics and hybrid materials with the same confidence and precision.

Our lab capabilities make ALTTRAN a versatile partner for companies developing components across a range of polymers. Whether you need to confirm compliance, improve durability, or support new product development, our testing services deliver accurate, repeatable data for better material decisions.