Consistent Quality.

Shorter Lead Times.

Better Service.

Rubber Mixing • ALTTRAN Technical Services (ATS) • Rubber Formulation Development

Delivering a better rubber mix through research, compound formulation, and testing experience.

At ALTTRAN and ATS, our mission is to deliver exceptional custom rubber compounds while providing an unmatched customer service experience. We understand that rubber companies have many options for rubber mixing, formulation development, and testing. That’s why we’ve tailored our services to support their success – offering rapid response, faster turnaround, and competitive pricing to help our customers meet or exceed their goals.

ALTTRAN RUBBER MIXING

Polymer types we mix:

| Butyl & Halobutyl | (IIR, CIIR, BIIR) |

| Carboxylated Nitrile | (XNBR) |

| Hydrogenated Nitrile | (HNBR) |

| Nitrile Butadiene Rubber | (NBR) |

| Chlorosulfonated Polyethylene | (CSM) |

| Ethylene Propylene Diene Monomer | (EPDM) |

| Natural Rubber | (NR) |

| Polybutadiene | (BR) |

| Polychloroprene | (CR) |

| Polyisoprene | (IR) |

| Styrene Butadiene Rubber | (SBR) |

| Nitrile/PVC | (NBR/PVC) |

ALTTRAN Technical Services (ATS)

Improving materials and processes:

Rubber formulation development

Lab to scale up production planning

Confirm ASTM D-2000 call-outs

Product performance evaluation

Raw material validation and recertification

Data development for technical marketing programs

Lab mixing

Custom rubber compound formulation

Compound Mixing

Molding Process Simulation with RPA

Rubber problem solving

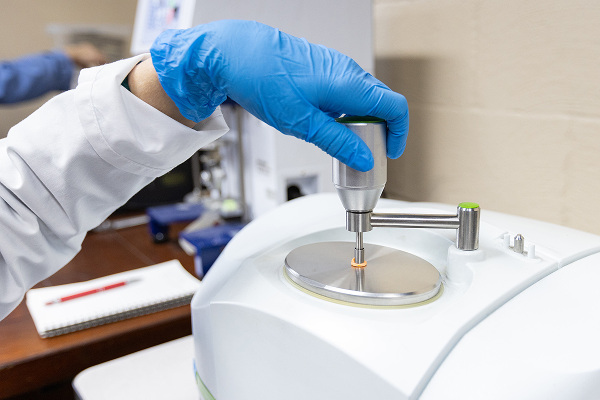

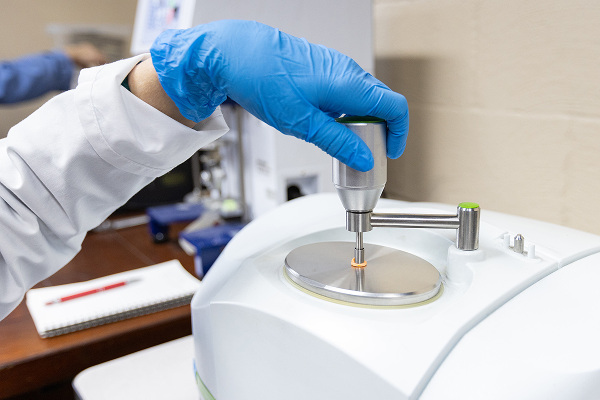

ATS TEST LAB

Analytical Testing

| FTIR | ASTM E 573 |

| FTIR – Microscope | ASTM E334 |

| TGA for Compound Analysis | ASTM E1131 |

| TGA for Rubber Composition | ASTM D6370 |

Unaged Physical Testing

| Moving Die Rheometer | D5289 |

| Rubber Process Analyzer | D6204/D6601 |

| Viscosity & Scorch | D1646 |

| Durometer | D2240 |

| Tensile Strength | D412 |

| Green Strength | D6746 |

| Tear Strength | D624 |

| Tension Set | D412 |

ALTTRAN RUBBER MIXING

Polymer types we mix:

| Butyl & Halobutyl | (IIR, CIIR, BIIR) |

| Carboxylated Nitrile | (XNBR) |

| Hydrogenated Nitrile | (HNBR) |

| Nitrile Butadiene Rubber | (NBR) |

| Chlorosulfonated Polyethylene | (CSM) |

| Ethylene Propylene Diene Monomer | (EPDM) |

| Natural Rubber | (NR) |

| Polybutadiene | (BR) |

| Polychloroprene | (CR) |

| Polyisoprene | (IR) |

| Styrene Butadiene Rubber | (SBR) |

ALTTRAN Technical Services (ATS)

Improving materials and processes:

Rubber formulation development

Lab to scale up production planning

Confirm ASTM D-2000 call-outs

Product performance evaluation

Raw material validation and recertification

Data development for technical marketing programs

Lab mixing

Custom rubber compound formulation

Compound Mixing

Molding Process Simulation with RPA

Rubber problem solving

ATS TEST LAB

Analytical Testing

| Butyl & Halobutyl | (IIR, CIIR, BIIR) |

| Carboxylated Nitrile | (XNBR) |

| Hydrogenated Nitrile | (HNBR) |

| Nitrile Butadiene Rubber | (NBR) |

| Chlorosulfonated Polyethylene | (CSM) |

| Ethylene Propylene Diene Monomer | (EPDM) |

| Natural Rubber | (NR) |

| Polybutadiene | (BR) |

| Polychloroprene | (CR) |

| Polyisoprene | (IR) |

| Styrene Butadiene Rubber | (SBR) |