Rubber Testing

Services

Rubber testing services for precision and performance.

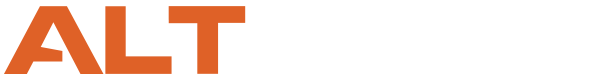

We provide accurate, consistent rubber testing services to ensure material performance meets industry standards. Our rubber testing laboratory follows ASTM-certified methods to verify critical properties, offering both standard material validation and custom testing solutions for specialized applications. We analyze unknown materials, identify contaminants, determine plastic or rubber types, quantify fillers, assess degradation, and support quality control. When formulation becomes a bottleneck, it slows innovation and sales. Our team works alongside yours to accelerate development, ensuring high-performance compounds while optimizing formulations, improving quality, and maintaining reliable production processes.

Need reliable rubber testing?

Share a few details and we’ll tailor the right analysis for your needs.

* Required

* Required

Rubber Lab Testing Updates

Our rubber testing laboratory continues to expand, delivering comprehensive rubber compound testing and analysis for various industries.

Using ASTM-certified methods, we evaluate critical material properties to support formulation improvements,

ensure batch consistency, and maintain production reliability.

Rubber Lab Testing Updates

Our rubber testing laboratory continues to expand, delivering comprehensive rubber compound testing and analysis for various industries.

Using ASTM-certified methods, we evaluate critical material properties to support formulation improvements,

ensure batch consistency, and maintain production reliability.

New Advanced Low-Temperature

Testing Capabilities:

From Lab Testing to

Full-Scale Production:

Better mixing starts with rubber compound testing. We establish mix procedures, confirm processing efficiency, evaluate cure rates, and test surface smoothness using our advanced lab extruder—ensuring a seamless transition from lab development to full-scale production.

Our Testing Services Support:

Our Testing Services Support:

Plastic Testing Solutions

At ALTTRAN Technical Services, we provide plastic and polymer testing solutions using ASTM-based analytical and physical laboratory methods. In addition to our core rubber testing, our capabilities include material identification, comparative analysis, and physical property evaluation. These capabilities use tools such as FTIR, optical microscopy, and thermal analysis such as TGA, to help determine composition, identify contaminants, and assess material behavior.